Professional Orthopedic Medical Equipment Manufacturer

At ZMD, we don’t just make products, we create hope. We are committed to providing the highest quality support for orthopedic medical care, becoming the most trustworthy partner for medical teams and patients, and pushing the level of orthopedic medical care to new heights!

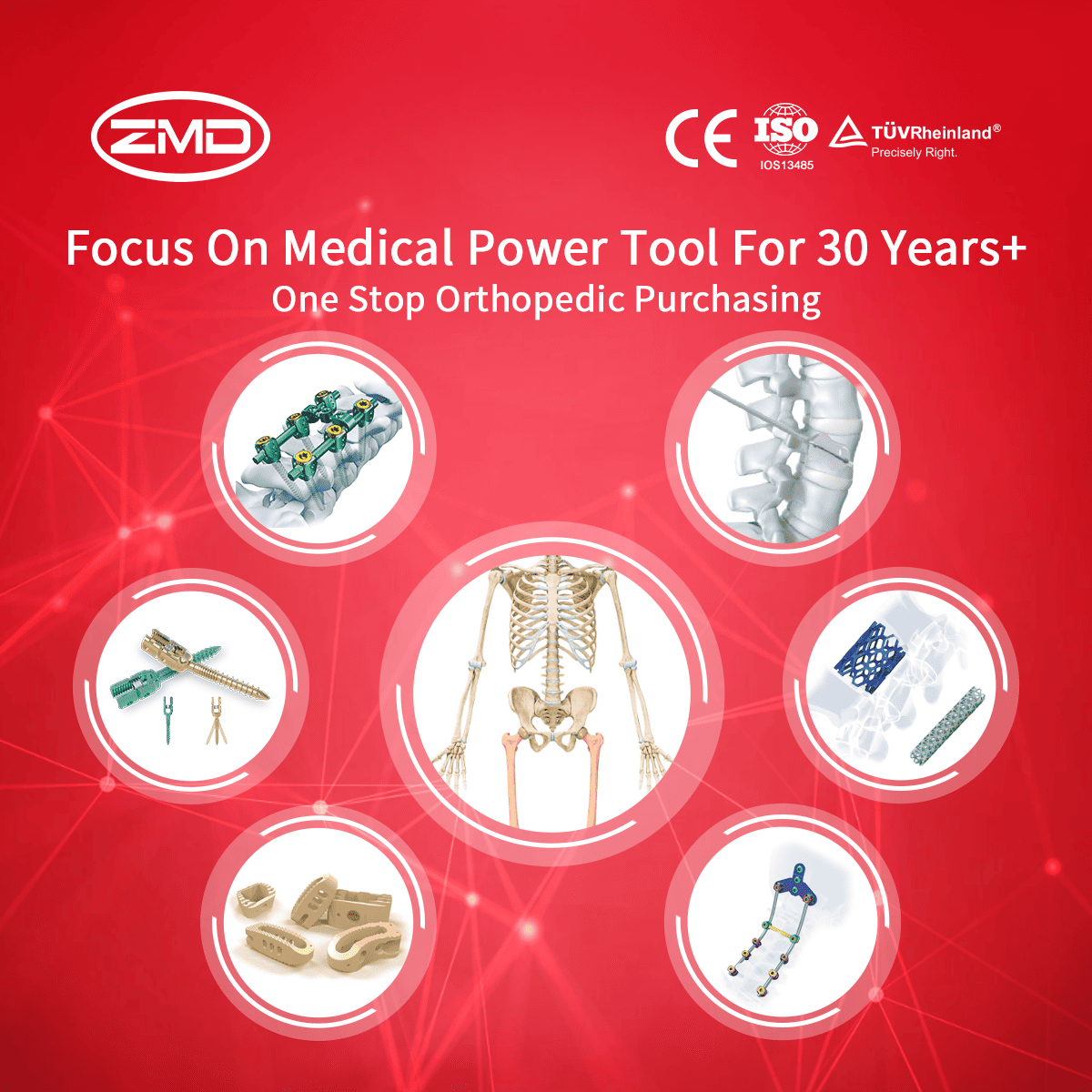

Product Category

Suzhou Sunan Jiemaid Medical Devices Co., Ltd. is a specialized high-tech enterprise integrating R&D, design, processing, manufacturing and sales of Class I, II and III orthopaedic (orthopaedic) instruments and ancillary surgical instruments, and is a member of China Medical Devices Industry Association and a director of Jiangsu Medical Devices Industry Association. The company strictly follows the national medical device production management requirements and has obtained ISO9001, ISO13485, SGS and EU CE certificates successively, which meets the domestic and international standard requirements

For Surgeons

With 35+ Years of Expertise, we are dedicated to providing exceptional patient care. Our Specialized Fracture Solutions offer a wide array of specialized orthopedic medical devices. Benefit from our Abundant Inventory and Rapid Delivery, supported by a strong inventory system and efficient logistics. Moreover, our Industry-Leading Training and Support programs help you improve your knowledge and skills.

For Distributors

A Comprehensive Product Portfolio presents your customers with a full spectrum of top-notch orthopedic medical devices, all obtainable from one dependable origin.

Our products feature Unmatched Quality, being crafted in accordance with the loftiest industry norms, thereby guaranteeing patient security, effectiveness, and dependability.

For Brand Side And Factory

One-Stop OEM and ODM Solutions: Capitalize on our all-inclusive OEM and ODM services to transform your inventive orthopedic medical device ideas into tangible realities.

Expert Design and Manufacturing: Our proficient team of engineers and adept technicians will engage in close cooperation with you to conceive, engineer, and fabricate top-quality orthopedic medical devices that precisely match your particular demands.

Production Process of Instrument Tools

01. Material

Purchase specific raw materials, such as metals or polymers for orthopedic products, from qualified suppliers in accordance with production schedules and product design requirements.

02.Cutting

High-precision cutting equipment is utilized to cut the liner according to the precise design size and shape of the product.

03.Milling

The high-speed rotation and precise movement of the milling tool removes excess material and produces a variety of complex shapes and features.

04.Drilling

Drilling with specialized drilling equipment for parts that need to be fitted with fixtures or connected to other components.

05.Polishing

Improvement of surface finish and reduction of surface roughness, resulting in better friction properties and biocompatibility during subsequent use of the part.

06.Anodizing

For metal parts, anodizing is performed to enhance surface corrosion and abrasion resistance as well as to improve surface color.

07.Cleaning

Ensure that the surface of the parts is clean and free of any residual contaminants to avoid adverse effects on product performance and human health during subsequent assembly and use.

08.QC

Comparison and analysis of test results with product design requirements and related quality standards to ensure that only qualified products can enter the next process or packaging links

09.Packing

Choose suitable packaging materials and packaging methods, and pack the products individually to prevent the products from being contaminated, collided or damaged during transportation and storage.

10.Stocking

Finished product warehouses need to maintain appropriate temperature, humidity and ventilation conditions to ensure that the quality of the product is stable during the storage period.

Excellent advantages of becoming our distributor

1.Rich and high quality product portfolio

We provide you with a comprehensive and high quality product portfolio covering all types of orthopaedic medical devices.

2.Unparalleled product quality

Quality is our lifeline, we promise you that every product we provide to you is carefully manufactured in accordance with the highest industry standards.

3.Attractive profit margins

Become a distributor of ours, and you’ll enjoy lucrative profits.

4.Convenient and efficient order fulfillment

We have a highly efficient order fulfillment process and a strong logistics network system.

5. Convenient and efficient order fulfillment

We have an efficient order fulfillment process and a strong logistics network system.

Frequently Asked Questions

The service life of a product varies depending on a number of factors, including the type of product, the individual patient’s condition (e.g., age, physical condition, activity level), and the site of use. Generally speaking, our high quality internal implants can function stably in the body for a long period of time under normal use and without complications. For example, bone splints and intramedullary nails usually meet the needs of the entire cycle of fracture healing, and some of our products can even be used in the body for a lifetime, which is subject to regular checkups and evaluations by a doctor to determine.

Most of our products are designed to follow international standards for orthopedic instruments. In some cases, such as the specification of the bone screws, they may be compatible with some other brands. However, in order to ensure the best therapeutic results and safety, we recommend the use of a complete set of matching products manufactured by us, as we have rigorously tested and optimized the synergies between our own products.

Our products are designed to maximize patient recovery after surgery. Due to the high quality and ergonomic design of our products, patients typically experience better stability and comfort after surgery, which facilitates fracture healing and functional recovery. For example, our spine products are effective in maintaining the normal sequence of the spine, reducing post-operative pain and accelerating the patient’s recovery. Recovery can also be affected by a variety of factors, including the quality of the surgery and the patient’s own ability to recover

We continuously invest in research and development, and the product update cycle is based on the technological development of the industry and clinical feedback. Each update is designed to incorporate the latest technological advances and clinical experience, such as the use of new materials to improve biocompatibility and optimized designs for easier surgery and faster patient recovery. New products often offer significant improvements in performance, safety and therapeutic outcomes

For elderly patients and patients with osteoporosis, our products have specialized design considerations. For example, in the design of the splints and screws, a fixation method more suitable for osteoporotic bone is adopted to increase the friction and grip to prevent loosening. At the same time, some of our products pay more attention to bioactivity in material selection, which helps promote bone healing and reduce the risk of complications due to osteoporosis

Our products are strictly sterilized before leaving the factory, and the package is well sealed. Before use in hospitals, if you need to disinfect again, you should follow the product instructions provided by us. Generally, you can use high temperature and high pressure steam sterilization, ethylene oxide sterilization and other methods commonly used in hospitals, but you need to pay attention to avoiding over-sterilization that will cause damage to the product’s performance. Different types of products may have different disinfection precautions, for example, products with special coatings may require specific disinfection conditions

Request A Free Quote

Or contact us to see our certificates

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86-18551239103

- sunanmedical@gmail.com