- Home

- About Us

- Products

- Trauma Internal Fixation System

- Spinal Internal Fixation System

- External Fixation

- Artificial Implants System

- Sports Medicine

- Power tools

- VSD System

- Instruments

- Medical supplies

- Blog

- Personnel Profile

- Contact Us

Phone line

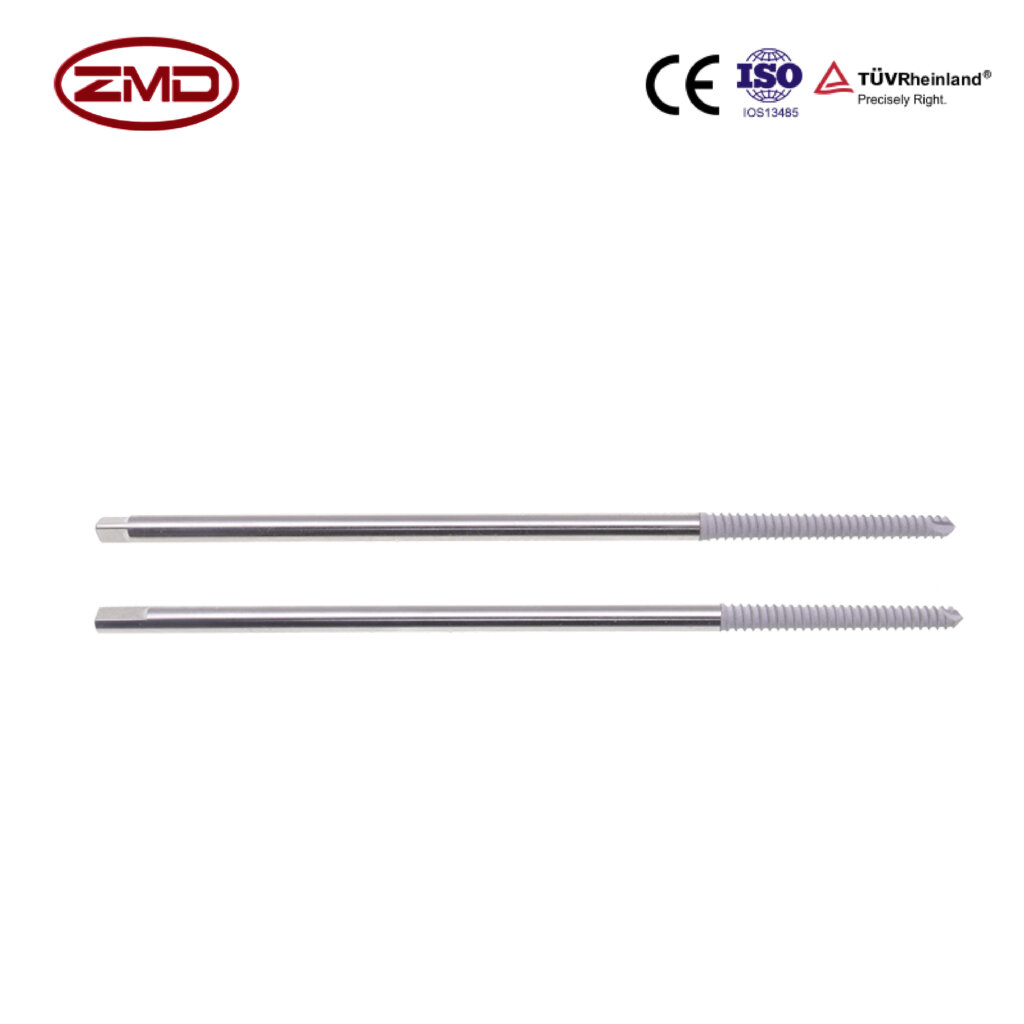

| Coding | Product name | Specification |

| 9005.0342 | Aluminium alloy bars | 3.5 mm locking |

| 9005.0343 | Aluminium alloy bars | 4.0 mm locking |

Oh yeah! I have to mention their payment options and discount offers, which are awesome! Those payment methods are as flexible as moving water and can be chosen freely according to our cash flow situation. And the frequent discounts, like a timely rain, have been moisturizing our financial statements time and again, and have had a rocket-like positive impact on our profits! With ZMD, I feel relaxed and at ease when it comes to purchasing!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Book Now

If you are looking for professional orthopedic medical product solutions, don’t hesitate to contact us now!

We are an integrated manufacturer specializing in orthopedic medical industry, providing high quality and reliable orthopedic medical products to customers worldwide.

Copyright © 2024 ASK Project